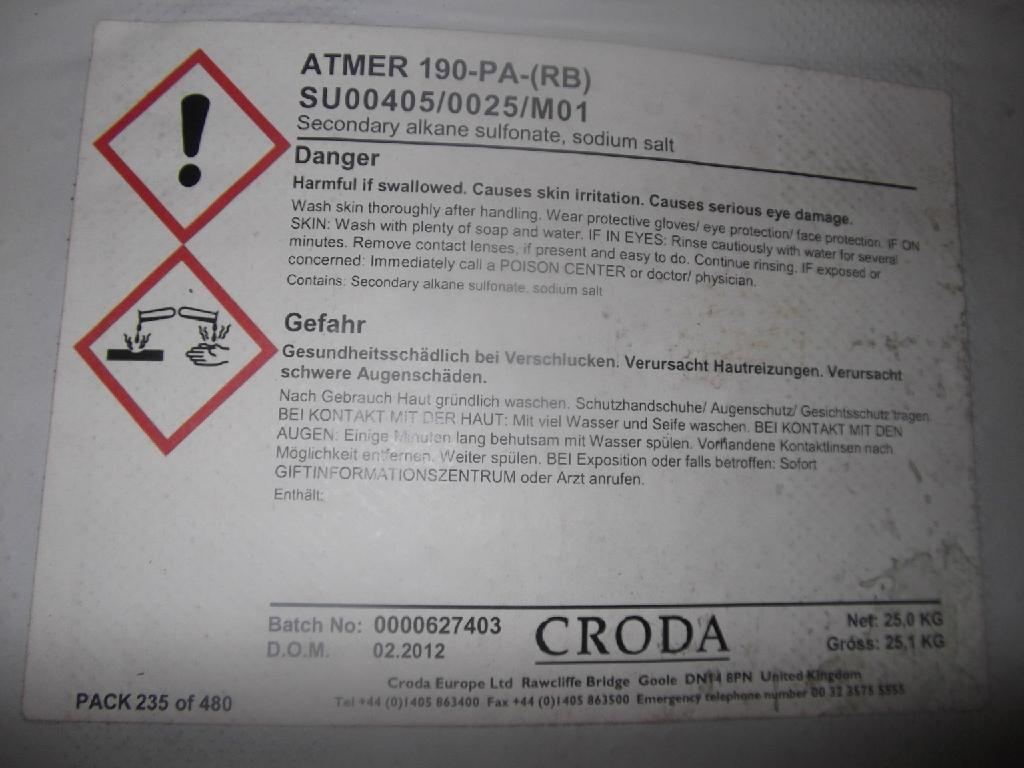

Model No.︰190

Brand Name︰Croda

Country of Origin︰United Kingdom

Unit Price︰CNY ¥ 56 / KG

Minimum Order︰1 KG

Chemical name: Sodium allyl

Molecular weight: 320 - 335 g / mol

Mechanism:

Atmer 190 can be used as "in use" or "external" type anti-static agent. As a "topical" anti-static agent used, you can immediately play effect, but the effect is short duration; as "the use of" anti-static agent used, can be uniformly dispersed in the molten polymer material, gradually over time to migrate to the molecular material surface hydrophilic adsorption of water molecules in the air (which also explains the high concentration of antistatic agent will have an impact on the printing and sealing and why would hygroscopic antistatic agents), the formation of conductive channel, reducing the surface resistance and improve polymer conductive surface, reduce the surface charge density, and thus make a lasting antistatic materials.

Performance advantages:

? long-lasting anti-static agent

? Excellent thermal stability

? transparent material does not apply

Basic features

ATMER 190 is a suitable styrene polymers, rigid PVC and TPU efficient internal antistatic agent and a wide range of food contact certification.

Applications

ATMER 190 is suitable for polyester, nylon, ABS, opaque PVC, styrene and other materials out of flat pieces of wood and a long-acting injection mold internal antistatic agent.

ATMER 190 can be used as an external anti-static agent (2% ATMER 190 with 98% of the water). Topically applied to all polymers.

ATMER 190 is not recommended for transparent applications because ATMER 190 will cause opacity.

Scope:

All polyolefin (LDPE / LLDPE / HDPE / PP), EVA

? PVC (non-transparent), PET / PET, PC, nylon, styrene (non-transparent), ABS, such as rubber and TPE.

Usage:

Atmer 190 can be used as "in use" or "external" type anti-static agent. As "the use of" additives and polymer materials have good compatibility. Practical experience shows that good results despite the mechanical dispersion, but can also meet the requirements of artificial dispersion.

"In use" recommended dosage:

Polyolefin film :0.1-0 .5%,

Polyolefin plastic injection 0.5-4%

Rigid PVC, was 1 cent (100 resin);

Add in the amount of ABS: 1.0% - 2.0%

Add in the amount of HIPS: 1.0% - 1.5%

Add in the TPU content: 1.5% - 2.0%

As "external" additive, it first dissolved in solvents such as water or ethanol concentration of 2-5%. Can be sprayed or coated on the surface.

Performance indicators:

Active ingredient (min): 90%

Moisture (max): 1%

Sodium (max): 6.5%

Melting Point: ~ 220 ℃

Soluble in water, slightly soluble in alcohol, the aliphatic and aromatic hydrocarbons, paraffin oil, low solubility.

Storage: dry, cool, ventilated place.

Health and safety: Atmer 190 non-toxic, does not irritate skin, eyes and respiratory system. Details refer to product MSDS.

Additional Information:

Europe allowed the U.S. to allow

Canada to allow Australia to allow

Japan to allow China to allow

South Korea to allow the Philippines to allow

Whether the plant extract food certification EC, FDA

We can provide food certification details.

Payment Terms︰ TT

Packing︰ 25KG/BAG